18 Oct Infrastructure and energy capital projects are notorious for being significantly delayed and over-budget. How can we mitigate these risks?

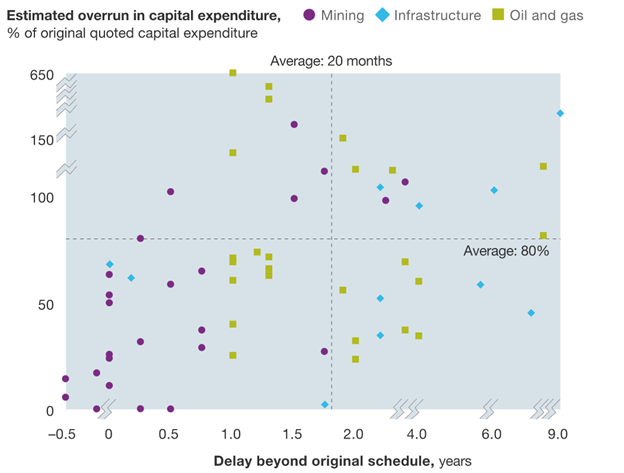

Civil infrastructure and energy capital projects are notorious for experiencing delays and cost overruns. As the following chart, prepared by McKinsey & Co. using the HIS Herold’s Global Projects Database, shows, most construction projects are delayed by an average of 20+ months and over-budget by an average of 80+%.

Source: Global Projects Database, HIS Herold, Nov. 19, 2013, herold.com; McKinsey & Co. analysis

These delays and cost overruns occur, accumulate, and often snowball as the project moves through its various stages – from planning, surveying, and permitting, to designing, constructing, and evaluating.

The underlying reasons for the delays and cost overruns plaguing the industry have been sliced, diced, and analyzed for years. Based on our first-hand civil engineering experience, we at Prezerv believe one of the root causes lies in the fact that the industry has been slow to adopt automated business processes and technological innovations. Fortunately, this situation is on the verge of change.

According to “The Engineering and Construction Company of the Future” (KPMG, May 1, 2019), all indications predict that market leaders are poised to invest in technology and innovation and drive change throughout the construction industry. Technology will be used to replace (or at least to supplement) many processes and applications across nearly every stage of a civil engineering project. KPMG’s 2021 Global Construction Survey, entitled “No turning back: an industry ready to transcend”, https://assets.kpmg/content/dam/kpmg/xx/pdf/2021/08/global-construction-survey1.pdf

applauds the progress achieved during the pandemic in terms of technology adoption and recommends that “both owners and engineering and construction companies should invest in relatively untapped technologies like AI, machine learning, robotic process automation and digital labor.”

Prezerv is specifically focused on the surveying and mapping stages of infrastructure projects. To date, many projects begin running late and over-budget right out of the gate because project teams develop or rely upon inaccurate surveys and maps of the project site. Availing themselves of recent improvements in drone and unmanned-aerial-vehicle (UAV) technology, some companies are developing new techniques that integrate high-definition photography, 3-D laser scanning, and geographic information systems, to efficiently create more accurate above-ground surveys. These developments represent progress, but they do not address the potential delays and cost overruns that lurk underground. This is where Prezerv comes in.

Accurately surveying what exists underground is orders of magnitude more difficult than producing above-ground surveys, for obvious reasons. Surveyors, planners, designers, and contractors typically begin by attempting to locate existing underground infrastructure so that the construction crew knows what to avoid while digging. To do this they must depend upon utility records, which are often neither available nor reliable. Discrepancies between real-life ground conditions and early survey estimates can require costly last-minute changes to a project’s scope and design. Inaccurate surveys and maps of the underground landscape can also result in costly incidents whereby, for example, a backhoe strikes an existing water main.

The Prezerv team is tackling this very problem. We make use of AI and nondestructive technologies, such as ground-penetrating radar (GPR), to efficiently develop accurate underground 3D maps.

Prezerv: mapping the underground so above-ground construction is on time and on budget.